Safety Relief Valves and Rupture Disc

Pressure Safety Valves

STANDARD SPECIFICATIONS

| Nominal Diameter at Inlet | DN 25 – DN 200 | 1″ – 8″ |

| Actual Orifice Diameter d₀ | 14 mm – 161.5 mm | 0.551 in – 6.36 in |

| Actual Orifice Area A₀ | 154 mm² – 20,485 mm² | 0.239 in² – 31.75 in² |

| Pressure | 0.12 bar – 413.7 bar | 2 psig – 6,000 psig |

| Temperature (in accordance with DIN EN) | -268 °C bis 538 °C | -450 °F bis 1,000 °F |

| Body Material | 1.0619, 1.4408, 1.7357 | SA 216 WCB, SA 351 CF8M, SA 217 WC6, SA 352 LCB, SA 351 CF3M, SA 995 Gr 4A CD3MN (Duplex), SA 494 M35-1 (Monel), SA 494 CX2MW (Hastelloy) |

| Valve Connection | Flange in accordance with ASME B 16.5 or DIN EN 1092 |

| Bellows Material (optional) | INCONEL 625 |

| Load Type | Spring-loaded |

| Make : | LESER |

Thermal Relief Valves

STANDARD SPECIFICATIONS

| Nominal Diameter at Inlet | DN 15 – DN 40 | 3/8″ – 1 1/2″ |

| Actual Orifice Diameter d₀ | 6 mm – 17.5 mm | 0.236 in – 0.689 in |

| Actual Orifice Area A₀ | 28.3 mm² – 241 mm² | 0.044 in² – 0.374 in² |

| Pressure | 0.1 bar – 850 bar | 1.5 psig – 12.328 psig |

| Temperature (in accordance with DIN EN) | -270°C to +450°C | -454°F to +842°F |

| Body Material | 1.4104, 1.4404, 0.7043, 1.0619, 1.4408 | SA 479 430, SA 479 316L, Ductile Gr. 60-40-18, SA 216 WCB, SA 351 CF8M |

| Valve Connection | Threads iaw DIN ISO 228-1, DIN ISO 7-1 / BS 21, ANSI / ASME B1.20.1. / Flange iaw DIN EN 1092-1 / DIN 2501., ASME B16.5 |

| Bellows Material (optional) | Stainless steel, Elastomer (EPDM), Hastelloy, Inconel |

| Load Type | Spring-loaded |

| Make : | LESER |

Pilot Operated Thermal Relief Valves

STANDARD SPECIFICATIONS

| Nominal Diameter at Inlet | DN 25 – DN 200 | 1″ – 8″ |

| Actual Orifice Diameter d₀ | 11 mm – 180 mm | 0.433 in – 7.087 in |

| Actual Orifice Area A₀ | 95 mm² – 25,446.9 mm² | 0.147 in² – 39.443 in² |

| Pressure | 2.5 bar – 426 bar | 36 psig – 6170 psig |

| Temperature (in accordance with DIN EN) | -48 °C to 200 °C | -54.4°F to 392°F |

| Body Material | 1.0619, 1.4408 | SA 352 LCB, SA 216 WCB, SA 351 CF8M |

| Valve Connection | Flange in accordance with DIN EN 1092, ASME B 16.5 or JIS 2220 |

| Load Type | Medium controlled |

| Make : | LESER |

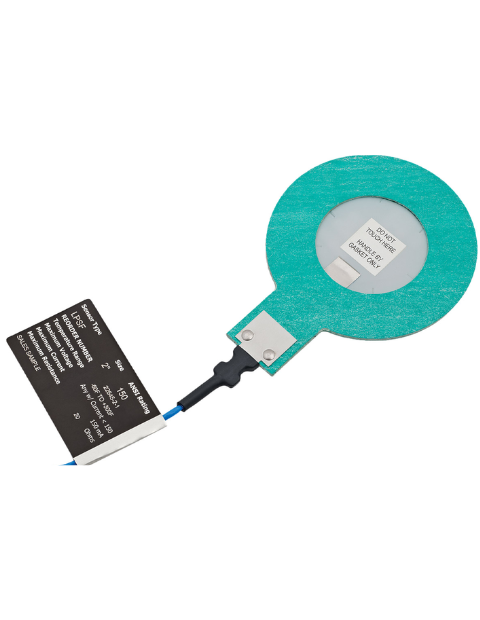

Rupture Disc

OsecoElfab’s rupture discs offer some of the highest performance specifications on the market. Excellently manufactured for accurate burst control, our reverse rupture disc range can operate at up to 95% of rated burst pressure. The technically advanced Opti-Gard provides a single disc solution across a range of burst pressures, and the PRO+ is excellent for isolating safety valves.

FEATURES

| • Designed for high pressure applications 2500 PSIG and above |

| • Internally sealed & externally welded |

| • Non-fragmenting, leak-proof design |

| • Assembly is Helium leak checked to 10^-8 atm-cc/s |

| • Non-torque sensitive |

| • High cycle rupture disc, tested to 48 million cycles |

| • Available in Hastelloy® C, 316 Series Stainless Steel, Inconel® 600 and |

| Monel® |

| • Make : OSECOELFAB |

Rupture Disc Holder

DISC HOLDERS

| Bolted Holder | Available with any combination of either weld-neck or threaded inlet and outlet connections |

| Booted Holder | The Oseco fluoropolymer-booted insert holder is used in applications where aggressive corrosives are present. |

| Double Disc Assembly | Enhanced environmental pollution control for processes using harsh chemicals |

| Forward Disc Holder | Our forward disc holders are designed for use with the forward acting bursting discs manufactured in North Shields (EMEA/APAC) |

| Insert Holder – FRDI / PRDI / RDI | Our insert holders are designed for use with most of the rupture discs manufactured in Broken Arrow (AMR). |

| OPR/OPK Holder | Designed to cater to multiple flange ratings |

| POSI/VRDI Holders | The POSI/VRDI holders are the primary holders for the POSIPRO and VAPRO rupture discs. |

| Pre-Torqued Insert Holder | Our pre-torqued insert holders provide a reliable solution for challenging installations or where misaligned piping is a concern |

| Reverse Disc Holder | Our reverse disc holders are designed for use with the reverse acting bursting discs manufactured in North Shields (EMEA/APAC) |

| Threaded Holder | Widely used on high-pressure applications up to 15,000 PSI |

| Union Holder | Oseco Union Rupture Disc Holders are ideal for applications where installation space is limited. |

| Make: | OSECOELFAB |

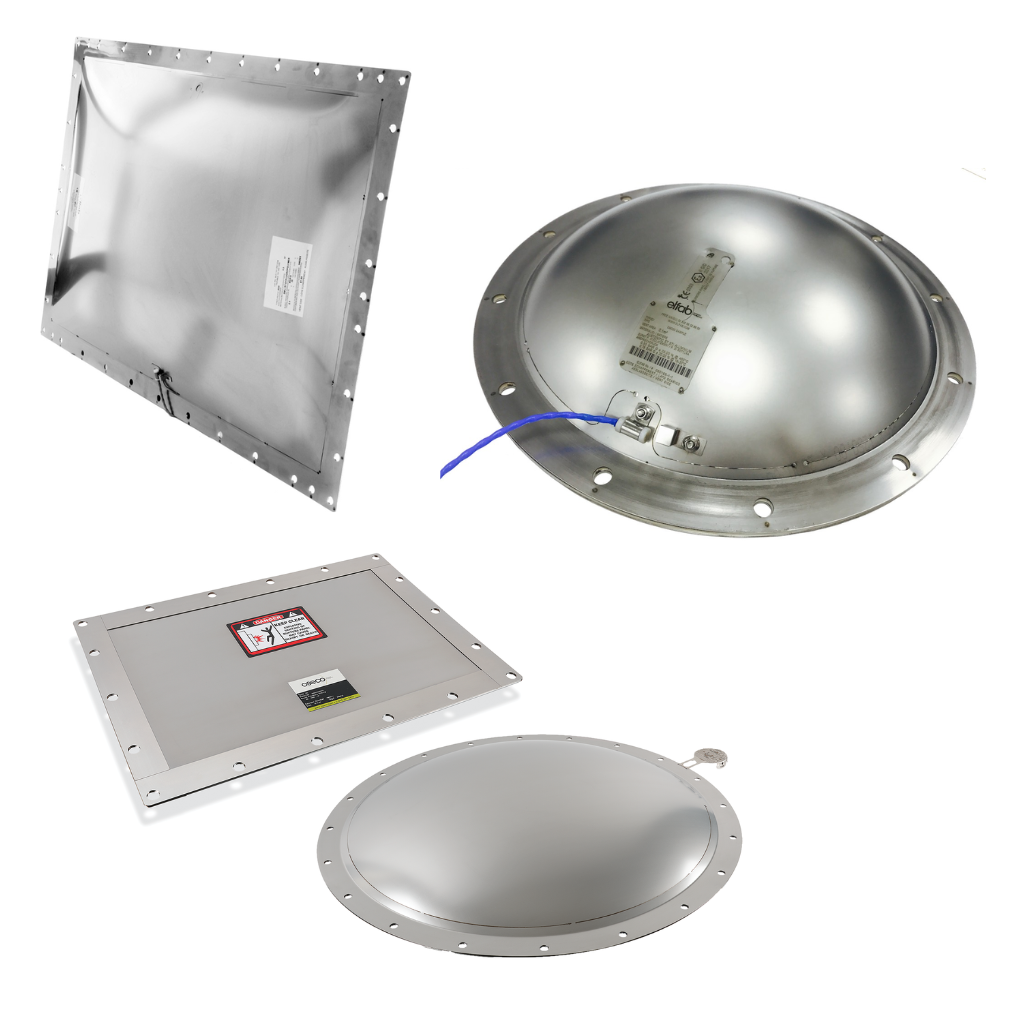

Explosion Vent

STANDARD SPECIFICATIONS

| CRP | The CRP is a lightweight explosion vent designed for use in power applications with electrical cabinets |

| CRVC | The CRVC is a heavy-duty vent with an option for internal insulation for high temperature applications. |

| EB Explosion Vents | Manufactured in North Shields, this full range of explosion vents includes single-skinned, multi-layered, flat, domed and sanitary designs |

| GLVF | The OsecoElfab GLVF is an excellent solution to protect bucket elevators during deflagrations. |

| Lift-Gard | With a robust construction and an integral frame, Lift-Gard offers explosion protection for vertical bucket elevators |

| MV Panel Range | Manufactured in Broken Arrow, the MV Panel Range is suitable for the most common explosion venting applications. |

| MV-BE | The MV-BE is a heavy-duty explosion vent with an integral frame to protect bucket elevators. |

| Thermal vent | Our thermal vent has a composite design that reduces heat loss when used in high-temperature applications |

| Make: | OSECOELFAB |