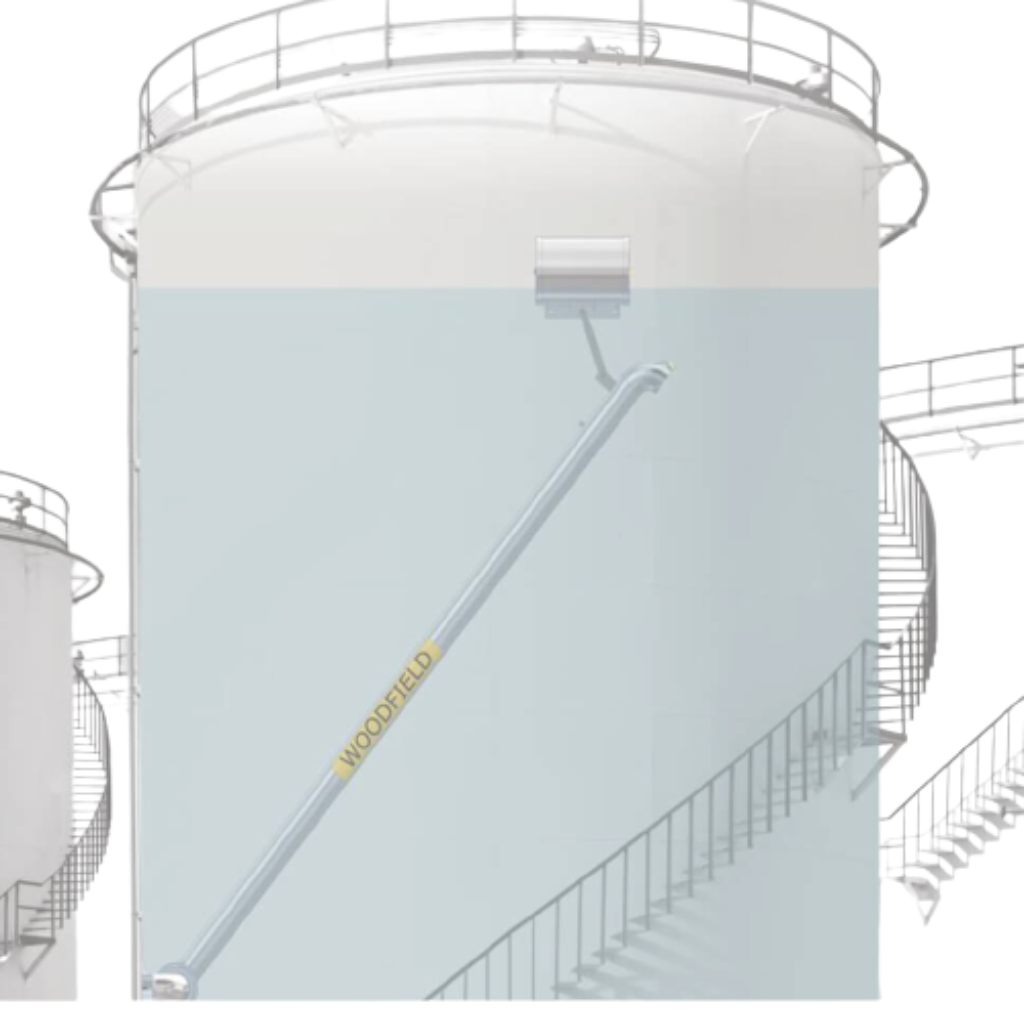

- Petroleum Loading / Unloading Arms

- Compressed Gas Loading / Unloading Arms

- Chemical / Industrial Loading / Unloading Arms

- Heated Loading / Unloading Arms

- Marine Loading / Unloading Arms

FEATURES

-

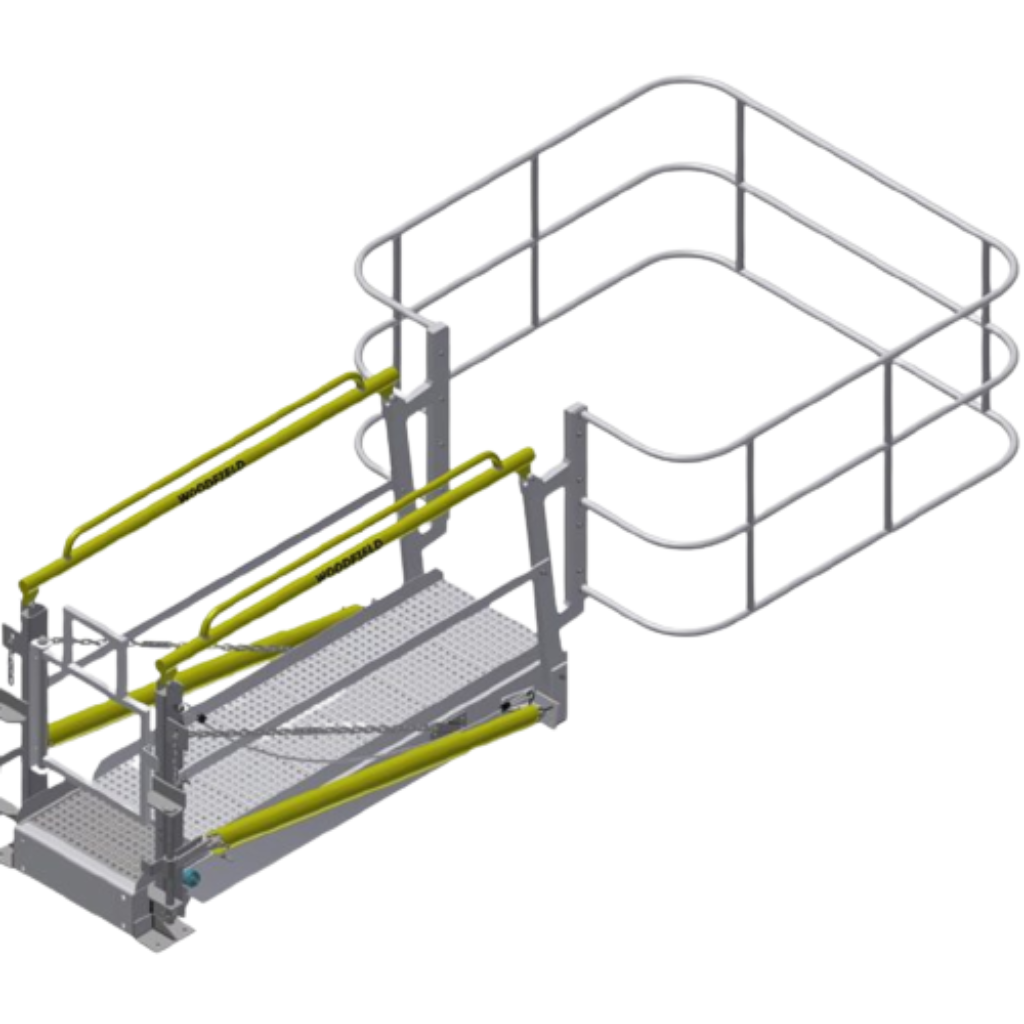

All loading & unloading arms are modular design with TTMA flanged connections of all the major components, thus allowing simpler arm configurations and superior maintenance capabilities. Inlet flange connection is ANSI #150.</.STRONG>

- The chemical and industrial products face various critical loading and unloading challenges. WSI’s range of Chemical loading & unloading arms are specifically engineered to handle the exact nature of each chemical or industrial, liquid or vapor being handled in and out of tank trucks, rail cars and ISO container tanks.</strong

- LNG and LPG Loading and Unloading Arms are available in 2”, 3” and 4”

- Design temperature: -196°C to +80°C for LNG Loading Arms, -40°C to +80°C for LPG Loading Arms

- All Gas Loading Arms are balanced by HD

compression spring

- This is why all WSI top and bottom loading & unloading arms are available as a “heated” model available with;

External steam or oil jacketing, orElectric heat tracing

|