Gaskets and Fastners

Metalic Gaskets

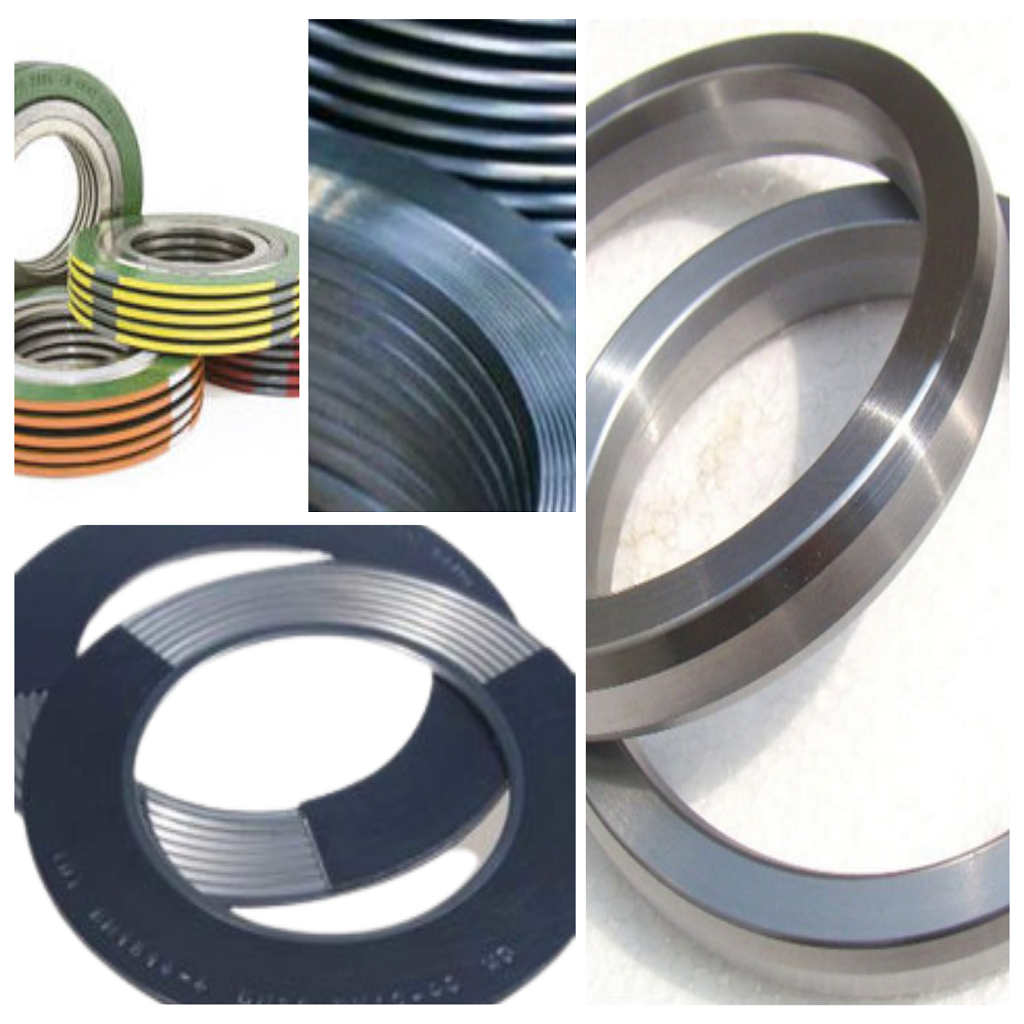

- Metallic Gaskets are used for sealing higher temperature and pressure applications, where non-asbestos materials will fail. Typical applications are for heat exchangers, compressors, condensers, pumps, and valves.

- Below are some of the metallic gasket materials and material manufacturers we work with to help you with your specific metal gasket needs.

- Metallic gaskets are fabricated from one or a combination of metals to the desired shape and size. Often used metallic gaskets are ring-type-joint gaskets (RTJ). They are always applied to special, accompanying flanges which ensure good, reliable sealing with the correct choice of profiles and material.

Ring Type Joint gaskets are designed to seal by “initial line contact” or wedging action between the mating flange and the gasket. By applying pressure on the seal interface through bolt force, the “softer” metal of the gasket flows into the microfine structure of the harder flange material, and creating a very tight and efficient seal.

ASME B16.20 covers materials, dimensions, dimensional tolerances, and markings for metallic and semi-metallic gaskets.

Non-Metallic gaskets are usually composite sheet materials are used with flat-face and raised-face flanges in low Pressure Class applications. Non-metallic gaskets are manufactured from aramid fiber, glass fiber, elastomer, Teflon® (PTFE), graphite etc. Full-face gasket types are suitable for use with flat-face flanges. Flat-ring gasket types are suitable for use with raised face flanges.

ASME B16.21 covers types, sizes, materials, dimensions, dimensional tolerances, and markings for non-metallic flat gaskets.

Semi-Metallic gaskets are composites of metal and non-metallic materials. The metal is intended to offer strength and resiliency, while the non-metallic portion provides conformability and salability. Often used semi-metallic gaskets are spiral wound and Cambrophile, and a variety of metal-reinforced graphite gaskets. Semi-metallic are designed for almost all operating conditions and high-temperature and pressure applications, and are used on raised face, male-and-female, and tongue-and-groove flanges.

ASME B16.20 covers mater>ials, dimensions, dimensional tolerances, and markings for metallic and semi-metallic gaskets.

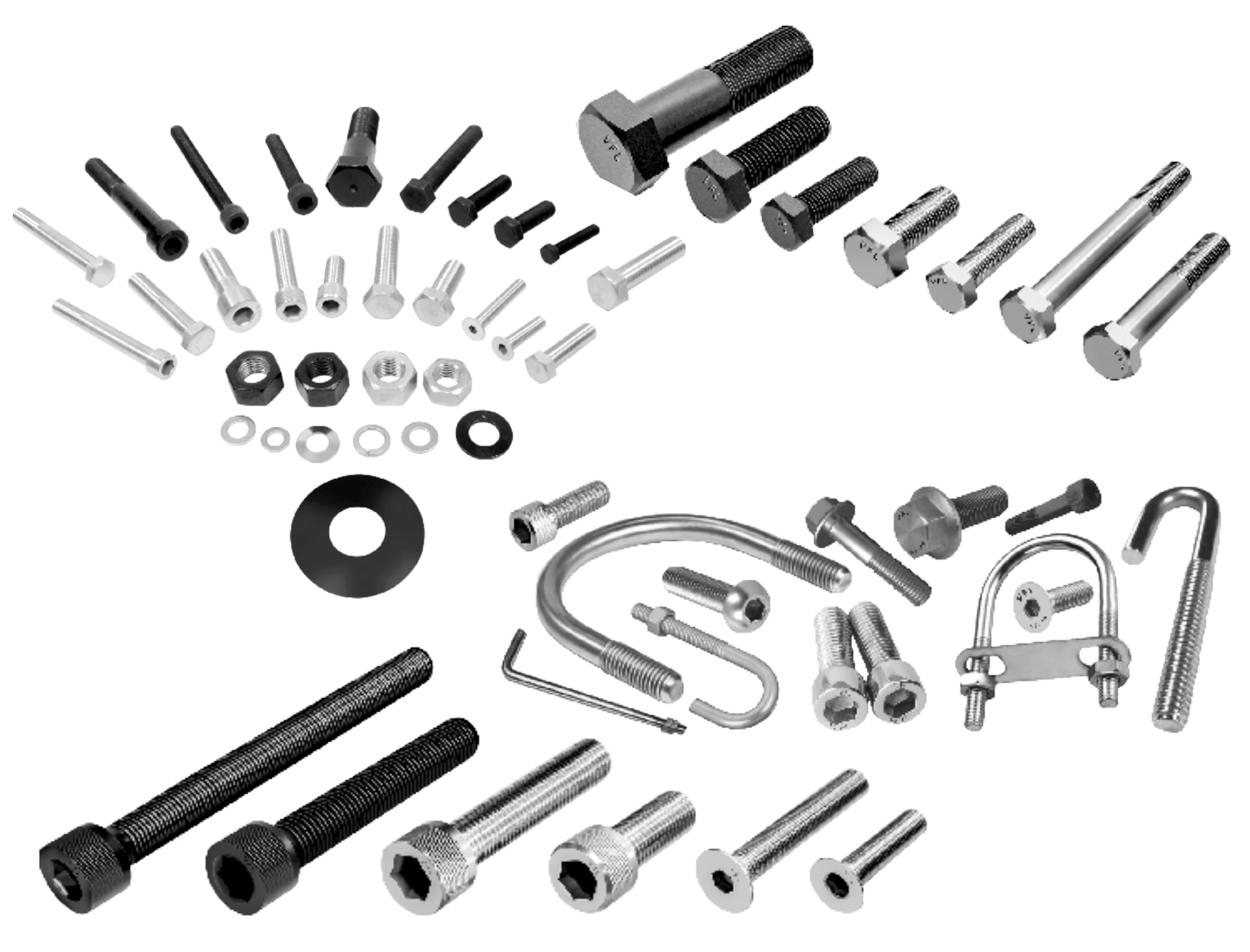

Fastners

Bolts ,Nuts ,Threaded Bars ,Bolt Washers ,U-Bolts ,Eye Bolts

Stainless Steel-304 ,304L ,316 ,316L ,316Ti ,310 ,202 and more High Tensile-8.8,10.9,12.9,B7/2H Carbon Steel Polymer/Elastomer Coated

Dia 8mm to 75mm & Length up to 2000mm

IS / BS / DIN / ISO / AS / ASTM / ASME or as per non-standards