Breather Valves, Flame Arresters and Emergency Vent

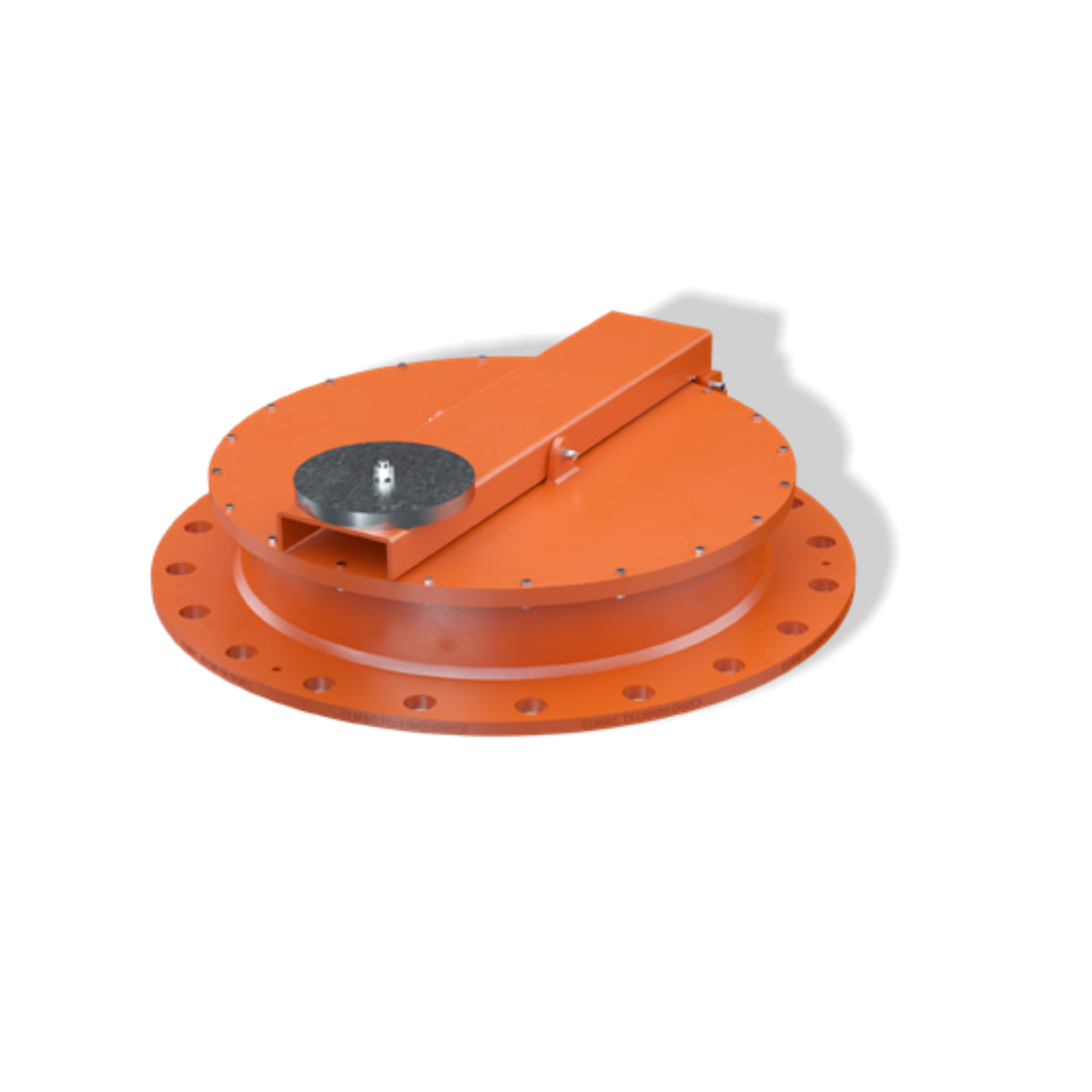

Pressure Vacuum Relief Valves(Breather Valves)

- Using proprietary software, the required flow area and the diameter of the Pressure Vacuum Relief Valve required to the relieve the normal venting requirements.

- Methods of Valve Sizing as per API-2000 – Co-efficient of discharge method / Flow curve Method.

- Our unique seal design offers ultra tight low leakage, reducing product losses, exceeding the requirements in API 2000 & ISO 28300.

- Minimum requirement is < 1SCFH at 75% of setting according to API 2000 (7th edition) & ISO 28300.

- High flow capacities – Skirted pallet for improved full lift performance.

- Low leakage rates – Air cushion knife edge design seat

End of Line Deflagration Arresters

- Size Range 15mm (3/8”) – 600mm (24”)

- Explosion Group IIA, IIB1, IIB2, IIB3, & IIC

- Operating Temperature upto +150°C

- Short-time burn capability

- E-Flow™ element design – uses less material and offers a greater free area to the flow

Inline Flame Arrestors

- Size Range 15mm (3/8”) -300mm (12”)

- Explosion Group IIA, IIB1, IIB2 & IIB3

- Operating Temperature up to +150°C

- Short-time burn capability

- E-Flow™ element design – uses less material and offers a greater free area to the flow

- Size range 15mm (3/8”) – 600mm (24”)

- Explosion Group IIA, IIB1, IIB2, IIB3, & IIC

- Operating temperature up to +150°C

- Short-time burn capability

- E-Flow™ element design – uses less material and

offers a greater free area to the flow - Ports for pressure and temperature ports

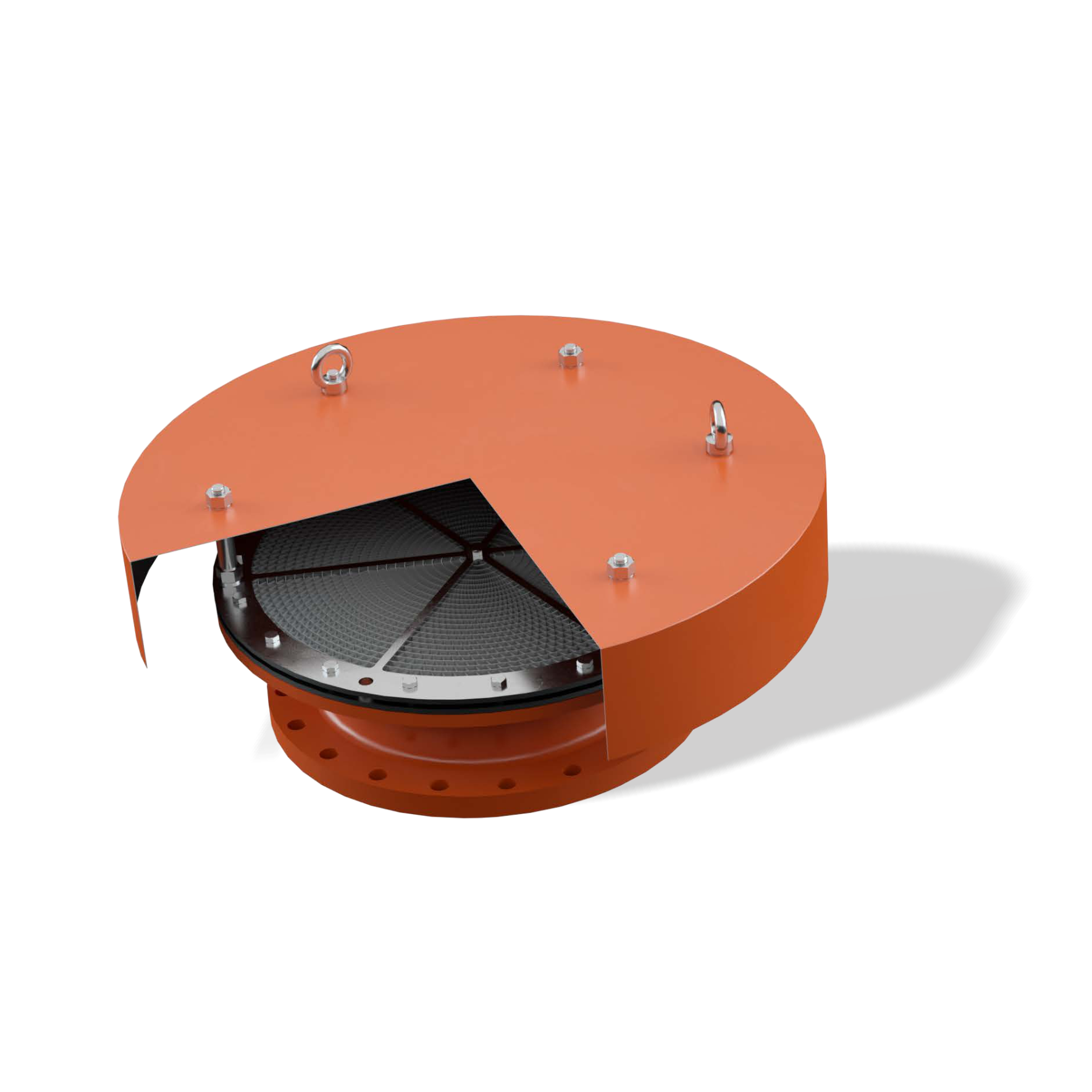

Emergency Relief Vents

- Anti-fouling self-draining element

- Significantly reduces contamination

- Prevents ingress of rain and dirt

- Reduces maintenance

- Extends service life

- Sizes up to 3″ (80mm)

- Carbon steel, stainless steel, aluminium

- 10” NB (DN250) to 24” NB (DN600)

- +8mbarg to +75mbarg

- Weight loaded construction

- Designed to API 2000/ISO 28300

- ATEX Directive 94/9/EC compliant

- Pressure only, vacuum only, combined options available